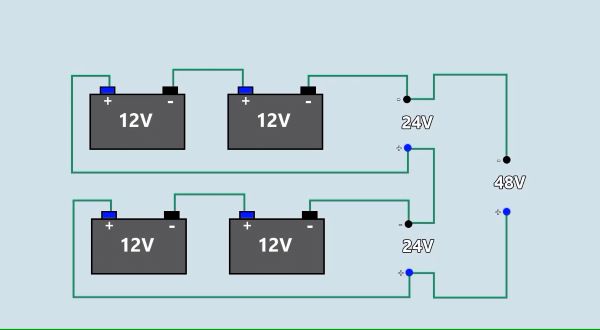

Common Voltage Systems Available

|

|

|

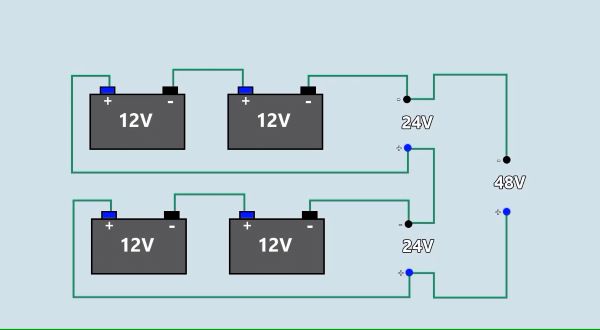

There are several battery voltages

to use when designing a system for

your camper. This article will focus

on camper vans but it can be applied

to other RVs and campers as well. |

|

|

Probably the most commonly used voltage is 12V

and for a good reason, this is the voltage

already used by the vehicle itself. In

simple systems, this probably would be the

best solution. But in most other systems,

there are other voltage choices that

probably would be better. Other voltage configurations are based on multiples of 12V. These include 24V, 36V and 48V. Of these, the most popular is probably 24V with 48V gaining in popularity; however, 36V is seldom used. |

|

When needing more power for operating

appliances, especially over a longer cable

distance, using higher voltages have an

advantage. This is due to the fact that

higher voltages will deliver the same amount

of power using lower current. The current is mostly what determines what

gauge (size) of wire you need to use. Higher

voltage with lower current also means you

will have less power loss. Plus, being able

to use smaller gauge wire, means lower

system cost and lower weight. With a simple

system, this may not amount to much, but as

the complexity grows, it becomes more

important. |

|

On most camper van builds, I gravitate

towards using 24V. This will keep our

current flow to half of that of 12V. But, we

will still need 12V and 120VAC for many

items. For 12V items, I will use a 24V to

13.8V DC-DC converter rated at 40A. This

will be used for lighting, vent fans and

other relatively low power items. For higher

powered items, I will use 120VAC and

sometimes 24V. The current flow for 120VAC

will be about 1/10th of that for 12V for the

same amount of power delivered.

|

|

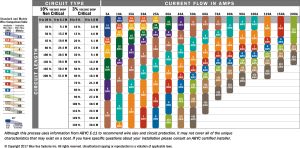

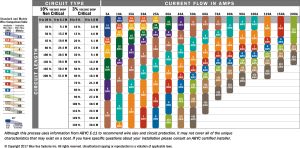

ABYC Wire Sizing

|

|

The American Boating and Yacht Counsel

(ABYC) has a wiring standard E-11. A wiring

chart can be found at www.BlueSea.com/resouces/1437

. This is a good resource to use for

determining the recommended wire gauge to

use. There are two columns on the left that

list lengths of wire for critical (no more

than 3% voltage drop) and non-critical (no

more than 10% voltage drop). Since a wire

run is a loop (power to on positive and

power return on negative), you will need to

double the physical length of cable for

looking up in chart. I explain this and how

to use the chart in a youtube video.

|

|

Auxilliary Power Unit

|

|

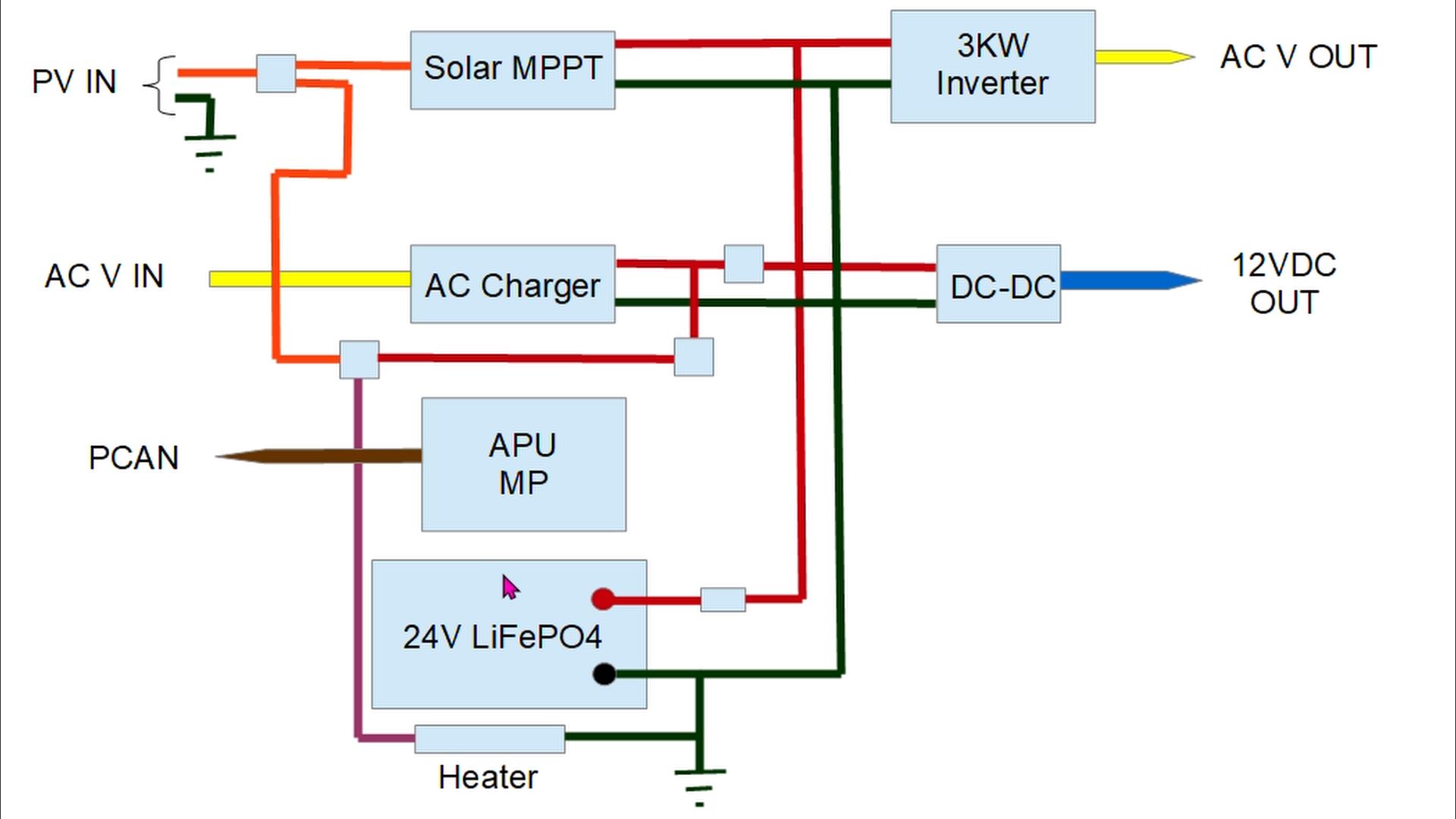

| I

typically bundle the LiFePO4 battery

cells, Battery Management System

(BMS), 3KW Sine Wave Inverter, AC

charger, Solar MPPT charger and a

24V to 13.8 DC-DC Converter all into

one package which I call an

Auxillary Power Unit (APU). This

keeps the inverter close to the

battery to minimize power loss. |

|

|

The package is completed by

including a microcontroller, display

and keypad. The microcontroller

communicates with other controllers

in the van using PCAN (Purrfect

Campers Area Network) which is a

specific CAN Bus protocol very

similar to OBDII used in all

vehicles today. This allows the APU

to be monitored and controlled with

a PCAN tablet or it can be

controlled using it's own keypad.

With all that said, the APU can be

removed from the van and used as a

stand alone power source since all

of it's external connections easily

unplug from it. |

|

A

really cool feature of the APU is,

once you select automatic mode, it

will turn the inverter

on whenever there is no shore power and there is no

power from the V-inverter (I'll

discuss the V-inverter a little

further down in this article). |

|

|

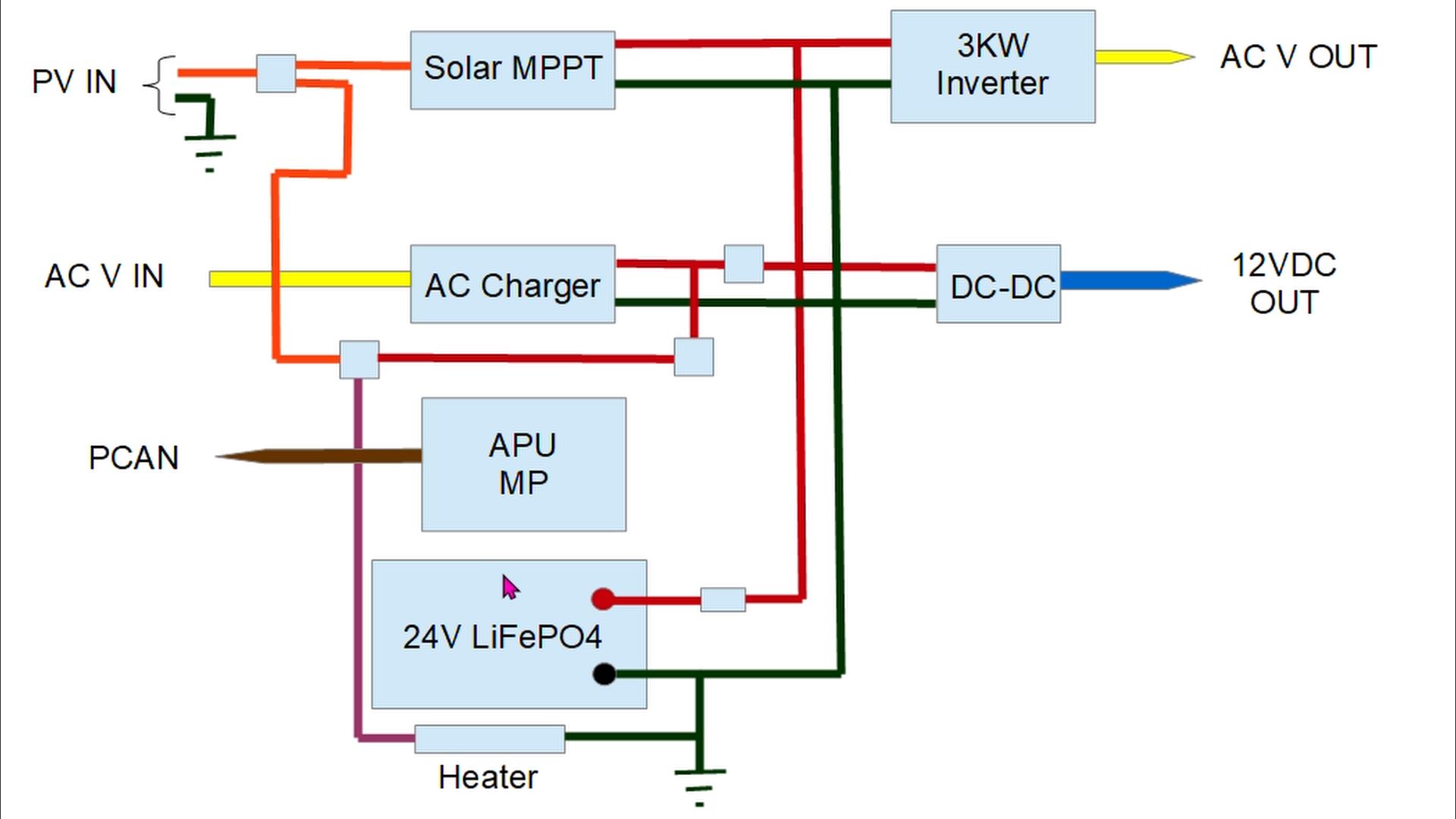

Taking a look at the wiring diagram

for the APU, the orange lines

represent the solar power coming in.

The red lines are the 24V bus. The

blue line is for 13.8V out. The

yellow lines are 120VAC. The black

lines are ground. The small

unlabeled square boxes are for

relays/contactors. Their main

purpose is to prevent charging when

the battery temperature is near or

below freezing. They will instead

divert power from the charging

source (solar or ac charger) to a

heating pad to warm the batteries.

Note that this uses power from the

charger sources and not the battery

itself. |

|

|

V-Inverter

|

|

One thing you will notice, is the APU

doesn't have DC-DC charging from the

engine's alternator. This is done using a

different method you probably haven't seen

before. I use a V-Inverter which is usually a 12V to 120VAC 2K

watt sine wave inverter placed under the

driver's seat and is connected to the van's

battery. It is switched on automatically

when the van is runing and the alternator is

putting out at least 13V. The advantages of

using this method include less loss of power

through long runs since the APU is generally

located at the back of the van, 120V is

available in the van without consuming power

from the APU, and reduced system cost since

we only need to run a 12 AWG power cable

between them.

|

|

Transfering Power

|

|

|

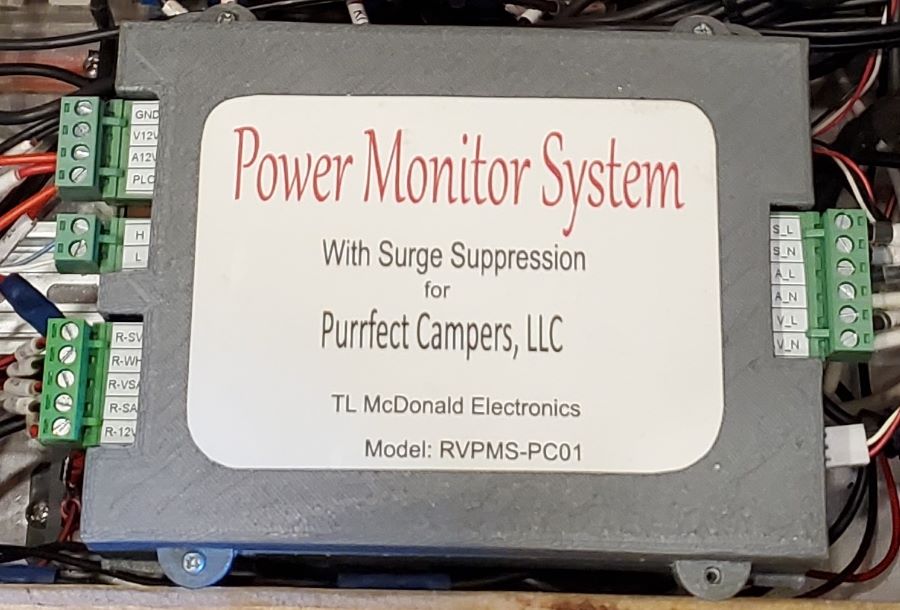

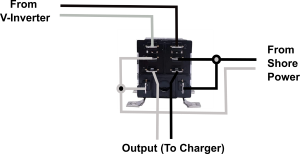

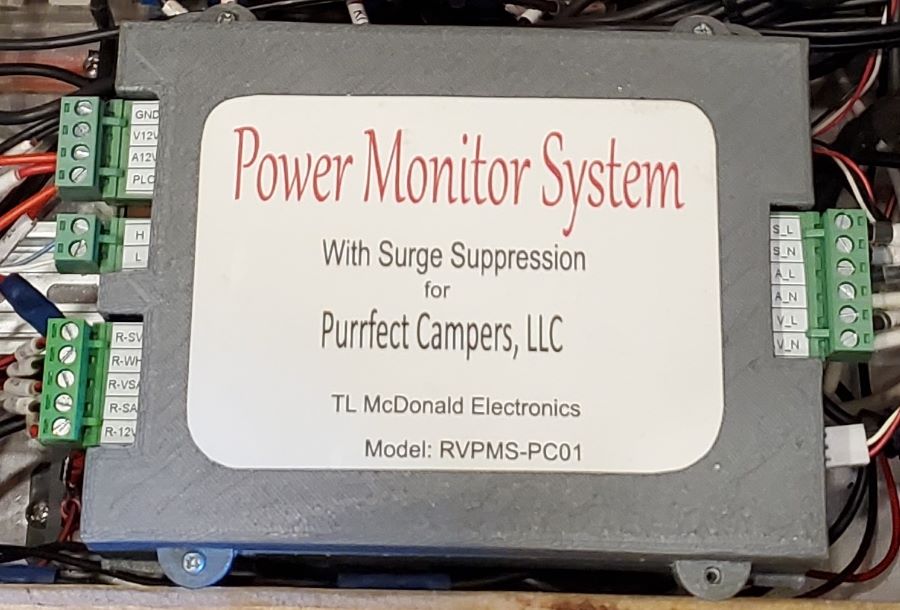

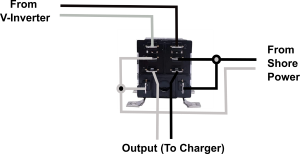

In the Omnia, the

120VAC power sources are all

controlled using the Power

Management System (PMS). It uses

small transfer contactors to control

which source to select from. An

alternative option is to use a

transfer contactor with a 120VAC

coil to swap between sources.

Transfer contactors are important

to prevent one source from feeding

power back to another source.

|

|

|

|

|

|

|

|

|

Discuss in ProBoard Forum

|

List of Resources

|

Video

|

|

|